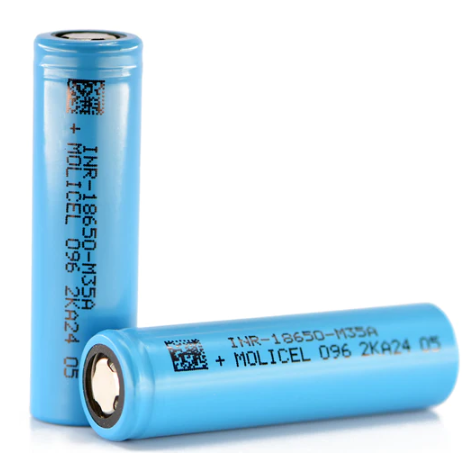

3.6V 30A Sony US18650 VTC6

Sony VTC6–High–Drain 30A

The Sony VTC6cell comes up with a typical capacity of 3120mAh, the nominal voltage of 3.6V. This is an absolutely excellent cell for anyone seeking high performance 18650 cells.

HIGHLIGHTS OF Molicel Sony VTC6

- Typical capacity: 3120mAh

- Minimum capacity: 3000mAh

- Nominal voltage: 3.6V

- End-of-charge voltage: 4.2V +/-0.05V

- End-of-charge current: 0.02C (About 62mA)

- End-of-discharge voltage: 2.00V

- Continuous maximum discharge:30A

- Cycle life: 300 cycles at 0.5C to 80%

- Initial impedance: 8mOhm – 18mOhm

- Weight: 46.4g +/- 1.5g

- Operating temperature: Charging 0°C ~45°C, discharging: -20°C ~ 60°C

- Storage temperature: -5°C ~ 35°C

- Energy Density: 631Wh/l

APPLICATION:power tools, high drain electronics and even battery packs

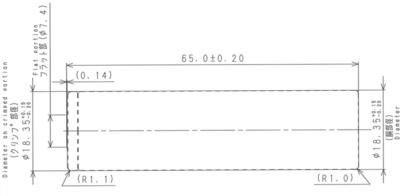

APPEARANCE

Shape: Cylindrical

Can : Steel

Diameter : 18.35 mm+0.15/-0.20mm

Height : 65.0 mm ±0.20mm

Weight: 46.6+/-1.5 g

cover of vtc5a

SE(Trade name of Sony Energy Devices Corp.)

ZZZZZ:Serial Nunber

Y:Year Supposing the year ’15 as X, the year ’16 as Y, the year ’17 as Z, the ye

ar’18 as A, Every

next year is counted as B, C, ・・・(Using an Alphabet letter)

M:Month January as A, the consecutive month as B, C,… (Using an Alphabet letter)

D:Day 01, 02, ・・・・29, 30, 31 (Using figures)

S:Electrode History A, B, C,・・ (Using an Alphabet letter)

Nominal Specification of Sony VTC5A

| Item | Nominal | Note | |

|---|---|---|---|

| Nominal Capacity | 3120mAh | Discharge at 0.2ItA,2.0Vcutoff after Standard Charge | |

| Nominal Voltage | 3.6V | - | |

| Charge Voltage | 4.20V | - | |

| Energy Density | 631Wh/l | - | |

| Item | Rating | Note | |

| Rated Capacity | 3000mAh | Discharge at 0.2ItA,2.0Vcutoff after Standard Charge | |

| Maximum Charge Voltage | 4.25V | - | |

| Cut Off Voltage | 2.0V | - | |

| Continuous Maximum Charge Current |

5.0A | Continuous | |

| 6.0A | Pulse | ||

| Continuous Maximum Discharge Current |

30A | With 80 deg temperature cut) | |

| 15A | (Without 80 deg temperature cut) | ||

| Allowable Environment Temperature |

Charge | 0~+60℃ | Refer to the cell temperature spec of 2.8 for cell surface temperature. |

| Discharge | -20~+60℃ | ||

| Weight | 46.6+/-1.5 g | - | |

※ Cell condition at the shipment

Cell Temperature Specification

| Temperature Range /Cell Surface Temperature Range | Upper Limited Charging Voltage | Maximum Charging Current | Charging Current Recommendation | ||

|---|---|---|---|---|---|

| Low ChargingTemperature Range | 0℃≦T<10℃ | A | 4.25V | 2.00A | 1.00A |

| B | 4.15V | 4.00A | 2.00A | ||

| Standard Charging Temperature Range | 10℃≦T≦45℃ | 4.25V | 5.00A | 3.00A | |

| High Charging Temperature Range | 45℃<T≦60℃ | 4.20V | 5.00A | 2.00A | |

At Low Charging Temperature range, condition A and B are both available. Recommended condition is B.

Part of Safety Tests

| ltem | Condition | Specification | |

|---|---|---|---|

| Heat cycle test | 1)Standard charge 2)Heat cycle at 75℃ 6h-30min→-40℃ 6h for 10cycles. 3)Storage at 20±5°℃ for 24 hours |

No leakage, No interception |

|

| Shock test | 1) Standard Charge 2) Drop the battery from 1.2m height onto P-tile for 3 times in each of X, Y and Z direction 3)Discharge at 10A,2.5V cut off 4)Standard charge 5) Capacity by discharge at 10A,2.5V cutoff |

No leakage, ≥2565mAh |

|

| Vibration test | 1) Standard charge | No leakage, ≥2565mAh |

|

| 2.)Vibration test under the following condition(5min. sweep, 1 hour for each axes) | |||

| 10~60Hz | 20.6m/s2 | ||

| 60~80Hz | 13.7m/s2 | ||

| 80~100Hz | 6.9m/s2 | ||

| 100~125Hz | 3.9m/s2 | ||

| 3) Discharge at 10A,2.5V cut off 4) Standard charge 5)Capacity by discharge at 10A, 2.5V cutoff |

|||

Over current protective circuit

The over current protective circuit shall operate charging at less than 5A.

The over current protective circuit or device shall operate discharging at less than 30A.

If the over 30A discharge occur, the allowable time of operating over current protection comply with the below table.

| Discharge current | 30~40A | ~55A | ~80A |

|---|---|---|---|

| Time | <40sec | <19sec. | <6sec. |

Storage Measures For Factory

1.Cell or battery warehouses should be set up independently.

Set up “No Fireworks” eye-catching signs in storage places.

It is strictly forbidden to stack combustibles and flammable items around.

2.The temperature of cell or battery warehouses should be controlled within the range of 20±5℃,

The maximum should not exceed 30℃,

The relative humidity should not be greater than 75%.

Keep the warehouse clean, dry and well ventilated, and do not store other items.

3.Cell or battery warehouses should be equipped with smoke and temperature alarm devices, and the alarm signal should be transmitted to a place where someone is on duty 24 hours a day.

4.Cell or battery warehouses should be equipped with independent external accident exhaust devices.

The accident exhaust devices should be interlocked with smoke and temperature alarm devices.

5.Cells and batteries should be neatly placed, not stacked too high, and storage facilities should be made of non-combustible materials, and anti-static measures should be taken.

6.The positive or negative pole position of each battery (cell) must be insulated to prevent short circuit protection measures.

7.Automatic sprinkler facilities should be set up in the battery warehouse.

8.The battery must not be stored at full capacity, and it is recommended to store it at 50% power.

9.Semi-finished batteries should be equipped with protective plates.

10.Waste batteries should be stored separately after being discharged.

11.Each fireproof zone of the battery and cell warehouse shall not exceed 250 square meters.

12.A sufficient number of spherical dry powder automatic fire extinguishers or sprinklers should be hung in the battery and cell warehouses.

13.The battery and cell warehouses should be equipped with 2 fire blankets each, and 1 special bucket for handling accident batteries.

PS:

1.Explosion-proof electrical equipment should be used in battery warehouses and aging rooms.

2.Faulty batteries and waste batteries must be placed in special treatment cabinets for isolation and disposal, and the use of explosion-proof sand buckets to deal with accident batteries is advocated.

Storage Measures For Daily Lithium Battery Users

1. For Lithium-ion batteries which need to be stored for a long time and not used, they should be kept in a state of 50%-60% charge. They should be recharged every 3 months and recharged every half a year.

2. Attention should be paid to moisture-proof and moisture-proof, to prevent squeezing, collision, etc., to avoid battery damage.

3. It is forbidden to use or place the battery at high temperatures (in hot sunlight or in very hot cars), otherwise it may cause the battery to overheat, catch fire or fail in function, and shorten its life.

4. It is forbidden to store in places with strong static electricity and strong magnetic fields, otherwise it will easily destroy the battery safety protection device and bring unsafe hidden dangers.

5. If the battery emits an odor, fever, discoloration, deformation, or any abnormality during use, storage, or charging, immediately remove the battery from the device or charger and disable it.

How to Custom 18650 Battery Pack

We have the unique ability to develop custom 18650 battery pack to fit your needs. Our expert team of chemists, engineers, and manufacturers who use proven chemistry and production methods that will get from spec to production fast. Slim, flexible, more powerful.

WHAT WE CUSTOM

WHY CHOOSE US

custom lithium battery packs collection

LG 18650 S3

LG 18650 S3 LG 18650 HE4

LG 18650 HE4 LG 18650 B4

LG 18650 B4 LG INR18650 MJ1

LG INR18650 MJ1 LG 18650 HE2

LG 18650 HE2 LG 18650 M26

LG 18650 M26

LG 18650 C4

LG 18650 C4 LG 18650 MG1

LG 18650 MG1 LG INR18650 HJ2

LG INR18650 HJ2 LG 18650 MH1

LG 18650 MH1 LG INR18650 F1L

LG INR18650 F1L Sanyo UR18650 AY

Sanyo UR18650 AY

Panasonic UR18650 NSX

Panasonic UR18650 NSX Panasonic UR18650 PF

Panasonic UR18650 PF Panasonic NCR18650 A

Panasonic NCR18650 A Panasonic NCR18650PD

Panasonic NCR18650PD Panasonic NCR18650 BM

Panasonic NCR18650 BM

Sanyo NCR18650 BL

Sanyo NCR18650 BL