Custom Battery Design Pricing Basics

All pricing secrets for your custom battery projects

When you are going to design or source a battery pack, there are so many questions you may ask:

How much should I pay for my custom lithium-ion battery?

How do I know which is the best battery supplier for me?

How would I make a final decision on the battery design?

How to study Value Engineering?

Some would just go and get several supplier contacts, ask for a bid, and then choose the cheapest or second to cheapest, is that a correct one?

Possibly No.

In this post, we are going to tell you some lithium Battery Industry secrets that you must know.

But I Bet, chances are you know nothing about them.

So, let’s cut the bullshit and start the roll:

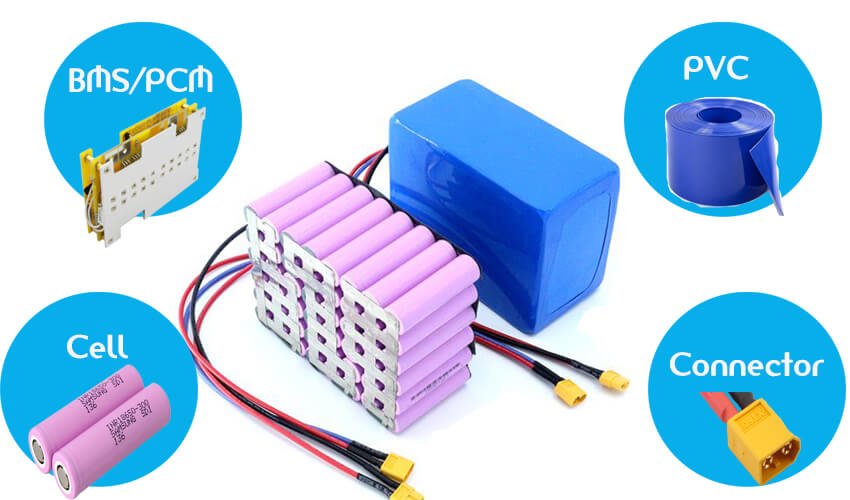

A lithium battery pack consists of 4 main parts, they are:

1 Battery Cell (cylindrical battery cell[like 18650 21700 26650], prismatic Cell [lipo and lifepo4 cell], Pouch cell[like lipo 103450] )

2 PCM or BMS : it’s used for battery management, common functions like short-circuit protection, over-charge protection, over-discharge protection, over-current protection, NTC. Monitor battery status like SOC[State of charge], SOH[State of health], SOP[State of power], Communication with the battery with CAN protocol.

3 Battery Enclosure: the enclosure could be PVC wrapped, plastic enclosure or metal enclosure. PVC is the most commonly seen type enclosure as it almost doesn’t require any MOQ.

4 Connector: the connector is a very important part of a battery pack although it’s not the top concern. Some connectors are still the expensive expense of the total battery cost.

In the next part, we are going to explain them in detail.

1 Battery Cell

For lithium battery cell, we want to explain in detail from two perspectives: Cell Format and Battery Material.

A Battery Cell Format:

From a Cell format perspective, the lithium battery can be divided into 3 categories: Pouch cells, Prismatic cells, and Cylindrical cells.

Prismatic or pouch cells are normally referred to as lipo cells, they are widely used electronic devices, almost all our portable devices are equipped with these types of cells, they are lightweight and don’t cause explosion, they are also widely used in RC Helicopters and Quadcopter, the Cons is they might need higher MOQ like 3k or 5k units per order.

Cylindrical Cells like 18650 or 26650 is the most used cells for battery packs as you can source easily from the market for any types of cells at any pricing from 0.5 USD to 4 USD per cell. So such battery cells, it usually doesn’t need so much MOQ but space is limited as it’s cylindrical.

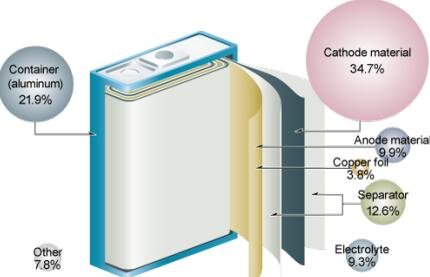

B Battery Components:

Different Factories will have different components of battery material, which is core to each battery cell maker, but Raw Materials have great pricing difference, some battery cells are can get 2200mah in capacity, but they are cheap because they sacrifice life circle or let’s say performance, for normal cells they go 500 circles but for some cells whatever you test with any testing machine, they rated 2200mah, but they will die much sooner as they have life expectancy like 300 circles.

Another important issue is there are two types of cells, capacity-focused cells and discharge-focused(high drain) cells, from our experiences, some would try to use the Capacity-focused cells to battery packs that may require High-discharge(high drain) cells like balance scooters.

Related News: My hoverboard EXPLODED under my feet Video

The Reason is simple too: the capacity-focused cells are usually cheap then discharge-focused(high drain) cells. but for devices like balance scooter, they might require C rate like 3-5C which is the Maximum of Capacity-focused cells but this is just the normal discharging rate for discharge-focused: in other words, the capacity focused cell(0.2-3C) will have problems of sudden death or explosion because they are running with max C rate all the time while the discharge-focused battery cell can easily handle such C rate requirement(5C-20C).

Takeaway: there is almost no way to define which is capacity-focused cell and which is a discharge-focused cell, they are also at the hands of the manufacturer. You need to test on your own.

C Battery Grade: Battery cells are Graded with A B C or further into A+ A- B+ B-. Let’s still take Samsung 18650 2200mAh Cell production for example,for each batch of mass production, before each cell goes to market, there will have a final process of Grading: for battery cells with capacity 2200mah and same life circle like about 500 circles will be labeled Grade A; battery cell with less than 2100mAh will be labeled grade B, battery cell with life circle less then 300 will be Grade C ( important: all above numbers are just examples only and do not apply to actual production and testing)

Why does this happen? it’s Simple: not each cell is produced at exactly 2200mAh and 500 life circles: some would 2400mAh, while some would 1800mAh, although battery cell maker like Samsung has high production control on cell performance, they simply can’t avoid such things to happen.

Battery cells are therefore divided in to A, B, C,D, according to the capacity, battery life circle and sometimes appearance.

Sadly enough, there is no industrial standards of what is Grade A and what is Grade B, the Grade standards vary from each manufacturer. Therefore, we can say, The So-called Grade A cell is almost SIMPLY a marketing Slogan, which is not much use but simply for promotion. But Branded cell take it more seriously, based on this, please always choose branded cells.

Sadly enough, there is no industrial standards of what is Grade A and what is Grade B, the Grade standards vary from each manufacturer. Therefore, we can say, The So-called Grade A cell is almost SIMPLY a marketing Slogan, which is not much use but simply for promotion. But Branded cell take it more seriously, based on this, please always choose branded cells.

Important Takeaway: for battery packs more then 4 cells, if the battery cell are not the same grade A cells, there is high chances of shorter life or even explosion.

Related: Wikipedia Battery Balancing

Actually this is not trying to scare you, check any post on Google for battery balance and you will know the truth: suppose we are charging 4 cells 2100mah,2200mah,2200mah,1950mah, let’s imagine if the 1950mah is charged full already, but the charger is still charging as there is 2200mah out there that don’t have enough juice. When the charging goes on, the battery has high chances of catch in fire or explosion (what if the mAh gap is even bigger, you can imagine the result: Disaster Or Nightmare)

Related: what if you are buying Fake Scam 18650 batteries , if you are buying fake Samsung or Sony cell simply because you want a cheap offer even less then any Chinese cells, chances are you are not a price killer, you just bring the nightmare to your customer as well as your company.

A boom will let all go to nothing, you don’t want Samsung Note 7 Recall story happen to you, don’t you? Even Samsung suffered a lot from it, what about you? Disappear or Go to Jail?

D Business Type: for most of the buyers, they want to buy directly from battery cell maker, and they insist to deal with battery cell maker only. This, actually, doesn’t make much sense. If you are reading this post, we suggest you to focus on the professionalism of the supplier you are talking to rather then trying to guess it’s cell maker or not.

Confused? Let’s go on to explain more.

Let’s Start with a simple question: who is the best manufacturer of lithium cells/packs? SAMSUNG, LG, SONY, PANASONIC, just name it, but why don’t you deal with them?

Let’s Start with a simple question: who is the best manufacturer of lithium cells/packs? SAMSUNG, LG, SONY, PANASONIC, just name it, but why don’t you deal with them?

If you contact Samsung, you would end in a slap your face as they want MOQ of 500k units per order.

Big Slap.

This is the same as many of Chinese cell maker, they don’t care your order at all. if they care, they die. Why? it takes half a day to let the cell maker machine to adopt a new model and finish your order in 30 minutes, will they do it?

BIG NO!

This is what they want: they want their machine to go 24/7, the cell maker, if not in high-end series, got only 10% in profit. They can make money only when they go 24/7.

Feel frustrated not dealing with cell maker directly? No, actually you are dealing with a third or fourth trader if not fifth trader/manufacturer.

Let’s back to the Samsung cell: if pack manufacturer can’t meet 500k units per cell per type(not for one month but for ongoing several months or years), they have to buy from traders!

Second-hand trader? You have the answer in your mind, don’t you?

2 PCBA/PCM:

PCBA is short for Printed Circuit Board Assembly (for PCM: Protection Circuit Module ), it is the board obtained after all printing solder paste on the PCB and then mounting various components like resistors, ICs (Integrated Circuits), capacitors and any other components like transformers depending on the application and desired characteristics of the board, basic functions like: input and output voltage and current control.

PCBA is a very important component for a battery pack.

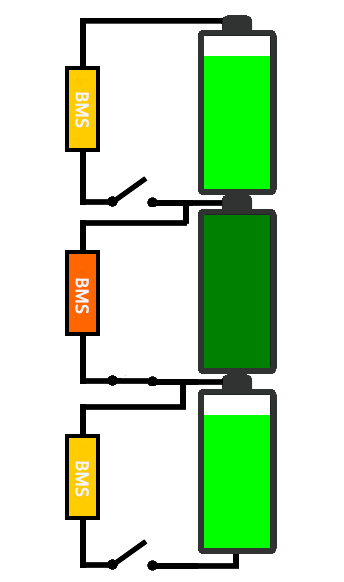

for large battery packs like 36v and above, you might need BMS(Battery Management System),you can deem it as enhanced PCBA. It is a mechanism that manages rechargeable battery pack, such as by monitoring its state, calculating cell data, processing cell data, protecting battery, controlling battery pack environment, and most important of all: balance the battery cells both on charging and discharging.

3 Battery Pack Design

(to be continued)

Prev Article: Why Choose Li-ion Battery Pack for Miner Lamp

Next Article: Advantages and Disadvantages of 21700 Battery

Hi

Very interesting content written and concise and useful

Topics are very useful, especially in the field of battery grade and battery vendors

Based on this content

We have a lot of confidence in your company and we are buying batteries from you

I hope we can work well together

Hello, my name is Dan and I’m in Florida gathering information as I am wanting to start building battery packs using cylinder type cells for the time being until I advance and have a need for others. Is there someone in R+D or tech support that I can contact to ask a few questions? I read the article above and just want to point out something that needs to be corrected I believe. Every time the term battery cycles comes up, it says circles instead of cycles. However I could see how circles would be for that meaning, I just have never heard it used in that way. If it’s circles over in your area then please send me a quick quip and call me a dumb ass one time and let’s move forward. I feel that this field is going to become even bigger than it already has become and jumping in this arena a little late, but better late than never. I wish everyone there the best prosparity and good fortune in all that you do. Thank you very much, Dan

thanks for the correction, please email tech@dnkpower.com