3.7V Sanyo UR18650ZY

UR18650ZY

Sanyo UR18650ZY cell is a wonderful cell with rated capacity of 2450mAh and nominal voltage of 3.7V. Many electric devices can be powered by Sanyo UR18650ZY cells. It has stable discharge voltage and light weight. This is a top-in class choice in 18650 cells.

HIGHLIGHTS OF Sanyo UR18650ZY

- Positive Terminal: Flat Top

- Nominal Capacity: Min.2500mAh

- Nominal Voltage: 3.7V

- Internal resistance:≤100mΩ

- Charging Method: CCCV(Constant Current Constant Voltage)

- Charging Voltage: 4.2±0.03V

- Charging Current: std.1,700mAh

- Charging Time: 3.0hrs.

- Energy Density: 535Wh/l 193Wh/kg

APPLICATION: a wireless headset, game player, or electric wheelchair, Notebook PCs, handheld devices,etc.

FEATURE:

1.) high capacity and stable discharge voltage

2.)light weight, small size and high performance

3.)small internal resistance

4.)outstanding discharge properties and storage Capacity

5.)Environment friendly

6.)long cycle life

7.)none memory effect

APPEARANCE

Shape: Cylindrical

Can : Steel

Diameter : Max. 18.60mm(with tube)

Height : Max. 65.00mm(with tube)

Weight: Max.48.0g

Nominal Specification of UR18650ZY

| Item | Specifications | Notes | |

|---|---|---|---|

| Rated Capacity | 2450mAh | 0.49A discharge at 20°C | |

| Capacity(Minimum) | 2500mAh | 0.50A discharge at 25°C | |

| Capacity (Typical) | 2600mAh | Reference only | |

| Nominal Voltage | 3.7V | 0.50A discharge | |

| Discharging End Voltage | 2.75V | - | |

| Charging Curent (Std.) | 1.75A | - | |

| Charging Voltage | 4.20±0.03V | - | |

| Charging Time (Std.) | 3.0 hours | - | |

| Contiuous Discharge Curent (Max.) | 5.0A | 0~+40°C | |

| Internal Resistance | ≤ 100mΩ | AC impedance 1 kHz | |

| Weight | less than 48.0g | - | |

| Operating Temperature | Charge | 0 ~ +45°C | - |

| Discharge | -20 ~ +60°C | - | |

| Storage Conditions | ≤ 1 month | -20 ~ +50°C | Recoverable Capacity: 80% |

| ≤ 3 months | -20 ~ + 40°C | ||

| ≤ 1 year | -20 ~ + 20°C | ||

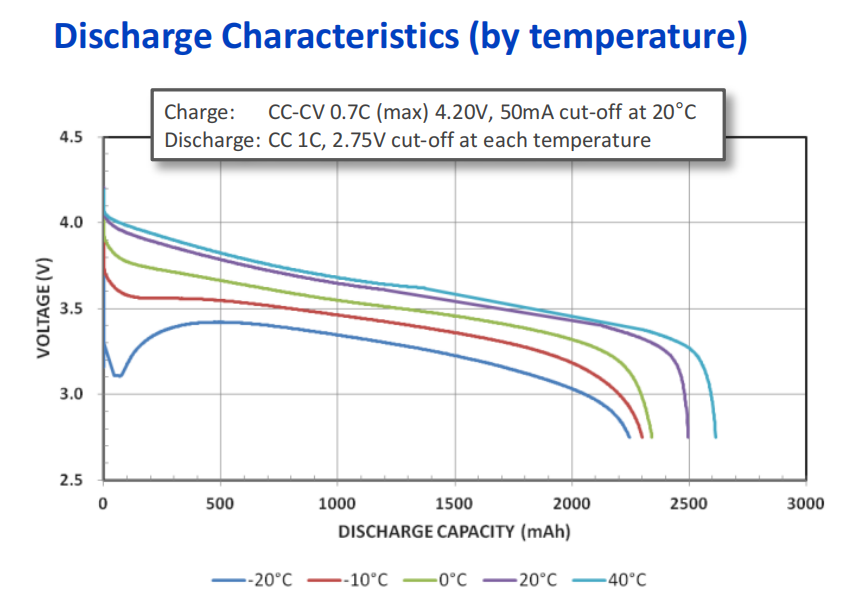

Electrical Characteristics Tests

| Item | Conditions | Criteria |

|---|---|---|

| Full Charge | The battery is charged at a 1.75A constant current until the voltage reaches 4.20V. The current is then reduced to keep a constant voltage of 4.20V. The total charging time is 3.0 hours at 25°C. | - |

| Capacity | (1) Within 1 hour after fully charging at 25°C as per item 6.1, the battery is discharged at 0.50A continuously to 2.75V at 25°C. (2) Within 1 hour after fully charging at 25°C as per item 6.1, the battery is discharged at 2.50A continuously to 2.75V at 25°C. |

≥ 300min. ≥ 54min. |

| Cycle Life | After the battery has been subjected to 300 repeated charge and discharge cycles (charged by CC-CV of 1.75A – 4.20V for 3.0 hours; discharged by CC of 2.50A to 2.75V at 25°C), the discharge time is measured as per Item 6.2, (2). | ≥ 38min. |

| Temperature Characteristics | (1) Within 1 hour after fully charging at 25°C as per item 6.1, the battery is stored at 0°C for 3 hours. The discharge time is then measured as per Item 6.2, (2) at 0°C. (2) Within 1 hour after fully charging at 25°C as per item 6.1, the battery is stored at 60°C for 3 hours. The discharge time is then measured as per Item 6.2, (2) at 60°C. |

≥ 30min. ≥ 50min. |

| Storage at Fully Charged State | After fully charging at 25°C per item 6.1, the battery is stored for 20 days at 60°C After storage, the battery is held at 25°C for 3 hours. Then, the discharge time is measured as per Item 6.2, (2). Then, the same battery is fully charged again and discharged a second time and measured as per Item 6.2, (2). |

≥ 30min. ≥ 40min |

| Storage at FullDischarged State | After fully charging at 25°C, the battery is discharged as per Item 6.2, (2). Then, the battery is stored for 20 days at 60°C. After storage, the battery is held at 25°C for 3 hours. Then, the discharge time is measured as per Item 6.2, (2). | ≥ 50min |

| Drop | After fully charging at 25℃, the cell is dropped 3 times in random directions from a height of 1 m onto a flat surface of concrete. | No rupture, no fire |

STANDARD TEST CONDITIONS:

All tests shall be conducted with new batteries delivered within the last 7 days. Tests shall be performed at a temperature of 25±2°C and a humidity of 65±20% (the standard temperature tolerance for Class 2 and the standard humidity tolerance for Class 20, respectively, as specified by JIS Z 8703, Standard Atmospheric Conditions for Testing). The precision of the voltmeter and ammeter used in the tests shall be higher than Class 0.5 as specified by JIS C 1102-2, Special Requirements for Ammeters and Voltmeters.

===============================================================================

Storage Measures For Factory

1.Cell or battery warehouses should be set up independently.

Set up “No Fireworks” eye-catching signs in storage places.

It is strictly forbidden to stack combustibles and flammable items around.

2.The temperature of cell or battery warehouses should be controlled within the range of 20±5℃,

The maximum should not exceed 30℃,

The relative humidity should not be greater than 75%.

Keep the warehouse clean, dry and well ventilated, and do not store other items.

3.Cell or battery warehouses should be equipped with smoke and temperature alarm devices, and the alarm signal should be transmitted to a place where someone is on duty 24 hours a day.

4.Cell or battery warehouses should be equipped with independent external accident exhaust devices.

The accident exhaust devices should be interlocked with smoke and temperature alarm devices.

5.Cells and batteries should be neatly placed, not stacked too high, and storage facilities should be made of non-combustible materials, and anti-static measures should be taken.

6.The positive or negative pole position of each battery (cell) must be insulated to prevent short circuit protection measures.

7.Automatic sprinkler facilities should be set up in the battery warehouse.

8.The battery must not be stored at full capacity, and it is recommended to store it at 50% power.

9.Semi-finished batteries should be equipped with protective plates.

10.Waste batteries should be stored separately after being discharged.

11.Each fireproof zone of the battery and cell warehouse shall not exceed 250 square meters.

12.A sufficient number of spherical dry powder automatic fire extinguishers or sprinklers should be hung in the battery and cell warehouses.

13.The battery and cell warehouses should be equipped with 2 fire blankets each, and 1 special bucket for handling accident batteries.

PS:

1.Explosion-proof electrical equipment should be used in battery warehouses and aging rooms.

2.Faulty batteries and waste batteries must be placed in special treatment cabinets for isolation and disposal, and the use of explosion-proof sand buckets to deal with accident batteries is advocated.

Storage Measures For Daily Lithium Battery Users

1. For Lithium-ion batteries which need to be stored for a long time and not used, they should be kept in a state of 50%-60% charge. They should be recharged every 3 months and recharged every half a year.

2. Attention should be paid to moisture-proof and moisture-proof, to prevent squeezing, collision, etc., to avoid battery damage.

3. It is forbidden to use or place the battery at high temperatures (in hot sunlight or in very hot cars), otherwise it may cause the battery to overheat, catch fire or fail in function, and shorten its life.

4. It is forbidden to store in places with strong static electricity and strong magnetic fields, otherwise it will easily destroy the battery safety protection device and bring unsafe hidden dangers.

5. If the battery emits an odor, fever, discoloration, deformation, or any abnormality during use, storage, or charging, immediately remove the battery from the device or charger and disable it.

How to Custom 18650 Battery Pack

We have the unique ability to develop custom 18650 battery pack to fit your needs. Our expert team of chemists, engineers, and manufacturers who use proven chemistry and production methods that will get from spec to production fast. Slim, flexible, more powerful.

WHAT WE CUSTOM

WHY CHOOSE US

custom lithium battery packs collection

LG 18650 S3

LG 18650 S3 LG 18650 HE4

LG 18650 HE4 LG 18650 B4

LG 18650 B4 LG INR18650 MJ1

LG INR18650 MJ1 LG 18650 HE2

LG 18650 HE2 LG 18650 M26

LG 18650 M26

LG 18650 C4

LG 18650 C4 LG 18650 MG1

LG 18650 MG1 LG INR18650 HJ2

LG INR18650 HJ2 LG 18650 MH1

LG 18650 MH1 LG INR18650 F1L

LG INR18650 F1L Sanyo UR18650 AY

Sanyo UR18650 AY Panasonic UR18650 NSX

Panasonic UR18650 NSX Panasonic UR18650 PF

Panasonic UR18650 PF Panasonic NCR18650 A

Panasonic NCR18650 A Panasonic NCR18650PD

Panasonic NCR18650PD Panasonic NCR18650 BM

Panasonic NCR18650 BM

Sanyo NCR18650 BL

Sanyo NCR18650 BL